H-type Layer Battery Cages for 40,000 Chickens in Tema, Ghana

We built a 40,000-layer chicken farm using H-type layer battery cages for a client in Tema, Ghana, with a daily production of over 36,000 eggs.

Basic Information of H-type Layer Battery Cages for 40,000 Chickens

Location: Tema, Ghana

Breeding scale: 40,000 laying hens

Chicken house type: closed chicken house

Farm type: modern intensive chicken farm with H-type layer battery cage system

Daily egg production: more than 36,000 eggs

Equipment used in the 40,000-layer chicken farms

The chicken farm uses advanced H-type battery cages, with each floor equipped with an automatic feeding system, automatic drinking water system, automatic manure cleaning system and automatic egg collection system. The equipment is highly automated and easy to operate, which greatly reduces labor costs.

- Automatic feeding system

- Automatic drinking water system

- Automatic manure cleaning system

- Automatic egg collection system

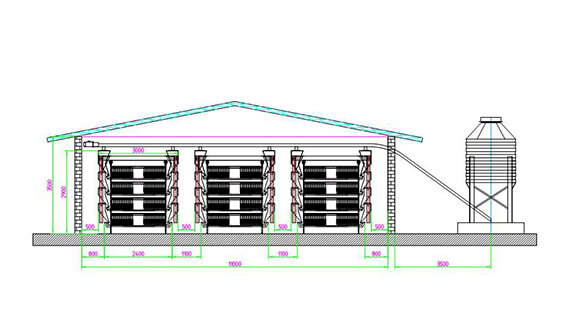

H-type Layer Battery Cages for 10,000 Chickens Design

The automated chicken farm with h-type battery cages for 40,000 layers planning follows scientific and efficient principles. The chicken house is spacious, bright and well ventilated, which is conducive to the growth and development of laying hens. Cage size, density, slope and other parameters are carefully designed to ensure that each laying hen has a comfortable living space and sufficient feed and drinking water.

Benefits Brought by Using H-type Layer Battery Cages

The benefits of using H-type battery cages chicken farms are very significant:

- Higher Egg Production: H-frame cages can increase egg production by up to 5-10% compared to floor housing systems.

- Reduced Feed Costs: Type H cages can reduce feed costs by up to 15% due to reduced feed waste and improved feed conversion.

- Lower Mortality: A well-controlled cage environment with good ventilation reduces the risk of disease and can reduce mortality by up to 20%.

- Collecting Eggs Easier: An automated egg collection system simplifies the egg collection process, saving time and labor costs.

After-sales Service We Can Provide to Our Customers

We provide customers with a full range of after-sales services, including:

- Equipment installation and debugging

- Regular maintenance and upkeep

- Technical guidance and training

- Emergency response and troubleshooting

With advanced equipment, scientific planning and comprehensive services, this A-type stacked cage chicken farm has become a model of high productivity and efficiency, bringing significant economic benefits to customers. We believe that through continuous innovation and optimization, we will continue to provide better solutions for the majority of chicken farming companies and help the healthy development of the layer chicken farming industry.